In the challenging field of product development, quality risk management is a daunting task. The 3DCS Advanced Analyser & Optimizer is an Add-on Module for 3DCS Suite of products that enables engineers to analyze variation results quickly and to make engineering decisions earlier and at lower cost.

The 3DCS AAO makes modelling easier by offering design engineers a set of analysers and optimizers that can be used to quickly optimize designs based on set criteria. It allows them to analyze the relationships between parts in an isolated environment, creating a ‘test lab’ for monitoring design changes.

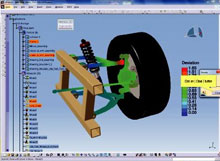

The add-on module from 3DCS consists of four primary components: Advanced Analyser, Critical Tolerance Identifier, Optimizer and Locator Sensitivity Analyser. The Advanced Analyser creates a matrix of Geofactors and tolerances, showing a global view of the model and the relationship between the model’s parts. The Optimizer optimizes tolerances based on quality criteria with the push of a button, while the Locator Sensitivity Analyser tests locator strategies and moves.

The advanced capabilities of 3DCS Advanced Analyser & Optimizer permits design and product engineers to work more efficiently on large models and quickly focus on key areas. The AAO saves time and helps gain engineers new insight into the design by facilitating testing different ‘what if’ scenarios in an isolated environment to find the best one before updating the model. Using the AAO, engineers have the power to optimize for cost or quality with the push of a button, making it easier to reduce costs on non-critical areas. In effect, the job of the design and product engineer becomes more efficient and effective.

Key Features

Create a Matrix to Get a Global View

View all of the products tolerances and Geofactors in a single colour coded matrix based on given specifications. Change the specifications with a drag bar to instantly identify trouble areas. Use to view and change many tolerances quickly on large models.

Optimize for Cost or Quality

Choose cost or quality goals and have AAO optimize your model for you. Look through the changes and keep the ones you like, updating the model only when you’re ready.

Determine Geofactors to Find Sensitive Areas

Find Geofactors and view them in the Matrix. These show the Geometric relationship, the multiplying effect of tolerances on one another so that you can isolate your most sensitive parts that have the greatest quality impact.

Validate Moves and Locator Strategies

Use Locator Sensitivity Analyser (LSA) to determine the effect of different locators on a part. Discover optimal assembly conditions, check the difference between different strategies and validate your move and assembly processes.

Make Changes and See the Results

Change tolerances, assembly processes or design characteristics and determine the outcome. Find issues and test solutions before building expensive prototypes or beginning production. See the results of your changes in the Matrix right away, without having to run additional analyses or simulations.

Key Product Highlights